HPK

The Rosenberger HPK system can achieve 280 A (50 mm²) at 85 °C up to 1000 V. With their excellent vibration and current capacity performance the HPK connectors are well-suited to typical high-voltage electric vehicle applications such as the connection between battery, inverter and PDU as well as to e-machine.

The range includes 1-, 2- or 3-pole connectors which for maximum flexibility can be used with copper or aluminum cables in different cable cross sections. Straight and angled cable connectors as well as corresponding headers are available, optional with HVIL (high-voltage interlock) or/and SVS (screw locking feature).

Product Portfolio

- Cable connectors 1-pole, 2-pole (3-pole on request)

- Cable connectors with or without SVS (screw locking feature)

- New versions with stamped outer contact element and material PBT

- Header optional with HVIL (high-voltage interlock)

- Cable assemblies

- ---

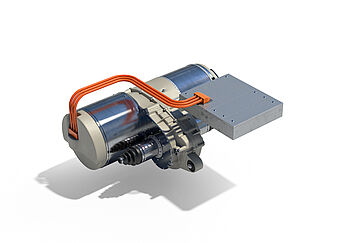

- Image shows 2-pole connector straight with HVIL and SVS

Features

- SHIELDED

- Current capacitiy (straight 50 mm²) 280 A at 85 °C

- Working voltage 1000 V DC

- Test voltage 3200 V DC

- Temperature range -40 °C to +140 °C

- IP class mated acc. to IP6K9K / IPX8 / IPXXD

- IP class unmated acc. to IPXXB

- Creepage (straight) ≥ 5.02 mm

- Creepage (right angle) ≥ 8.9 mm

- Clearance (straight) ≥ 4.91 mm

- Clearance (right angle) ≥ 9 mm

- Engine vibration SG2 acc. to LV, similar to V1 acc. to USCAR

- Mating cycles ≥ 50

- Cross sections 16 mm², 25 mm², 35 mm², 50 mm²

- New versions with stamped outer contact element and material PBT

- Different axis possible for the connection of the header

- ---

- Image shows 2-pole connector right angle cable down with HVIL and SVS

Image shows 2-pole connector right angle cable up without HVIL, without SVS

Benefits

- Versatile product range

- High temperature and vibration performance

- Design makes these series easier to assemble, creating faster processes and higher quality

- Optional with HVIL (high-voltage interlock)

- Cable connectors with or without SVS (screw locking feature)

- ---

- Image shows 2-pole header, outgoing busbar straight, with HVIL

Image shows 3-pole connector (on request)

Applications

- E-Machine

- Battery to PDU

- PDU to e-machine

Rosenberger Series Code H4

Image shows application to e-machine (3-phases)